|

| May 19, 2015 | Volume 11 Issue 19 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Tube connection advance speeds assembly of instrumentation systems for pressures up to 22,500 PSI

Combining the make-up simplicity of compression-style connections with the strength of cone and thread, Parker's new flared cone connection (FCC) technology is designed for working pressures as high as 22,500 PSI (1,550 bar).

A breakthrough in high-integrity tube connection technology that offers instrumentation system designers and installers major performance and time-saving advantages is now available from Parker Hannifin, a global leader in motion and control technologies.

Designed for working pressures as high as 22,500 PSI (1,550 bar), the new "flared cone" technology advances the performance of compression-style tube connections. It provides users with a simple and reliable means of speeding the assembly of instrument tubing systems for use in higher-pressure applications -- especially in the oil and gas industries.

Developed by Parker Autoclave Engineers, the new flared cone connection (FCC) technology is a significant advance on the type of "cone and thread" tube connections pioneered by the company.

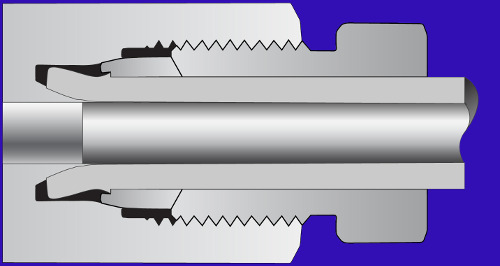

Parker Autoclave Engineers' patent-pending FCC technology is based on a single-sleeve, compression-style system. However, unlike conventional designs, the tube end is flared to prevent any possibility of ejection and also provides the connection's primary metal-to-metal seal.

Parker's new tube connection technology uses a flared cone design that prevents tube ejection and forms the primary metal-to-metal seal, with the compression sleeve providing a redundant second metal-to-metal seal for enhanced safety.

When the gland nut is tightened, the inside surface of the anti-ejection flare mates with a cone in the fitting or valve. The compression sleeve then mates with the body of the component to form a second, redundant, metal-to-metal seal.

This dual-seal approach has a major reliability benefit: in the unlikely event that the primary seal fails, the secondary seal preserves the integrity of the connection. Installing a flared cone connection is simply a matter of screwing the gland nut into the fitting or valve and tightening it to the prescribed torque.

The new flared cone connections are much simpler to make up. Installers can typically complete the task in less than 4 minutes, after only minimal training. This time-savings can result in significant cost reductions on installations with a large number of tube connections. Flared cone connections are also especially cost effective in applications where leaks caused by vibration are an issue.

To find out more, contact an engineer at Parker Autoclave Engineers (814-860-5700) or go to www.autoclave.com.

Source: Parker Hannifin

Published May 2015

Rate this article

View our terms of use and privacy policy